high quality slurry pump metal lined parts

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MoreStep 3

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read More>Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MorePacking the box seal

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read Morefactors-to-consider-when-choosing-a-slurry-pump

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MoreDefinition of dredge and slurry pumps

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MoreWA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MoreSlurry pump vs mud pump

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

high quality slurry pump metal lined parts...

high quality slurry pump metal lined parts 【high quality slurry pump metal lined parts】

Read More

Popular articles

- - Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

- If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

- It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

- Slurry pump seals

- These conditions include

Latest articles

-

Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

-

To find out more about Aier slurry Pumps, please >contact us.

-

Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

-

Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

-

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

-

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

Links

- One of the main advantages of fiberglass reinforced pipe is its resistance to corrosion. Unlike traditional metal pipes, FRP pipes do not corrode when exposed to harsh chemicals or environments, making them ideal for use in industries such as chemical processing, wastewater treatment, and oil and gas extraction. This corrosion resistance also helps to extend the lifespan of the pipes, reducing the need for frequent maintenance and replacement.

- In conclusion, GRP rectangular tanks represent a modern and efficient solution for various storage challenges. Their robust construction, resistance to corrosion, and customizable design make them a preferred choice across industries. Whether it's for commercial, industrial, or domestic use, investing in a GRP rectangular tank ensures a reliable, durable, and cost-effective storage option that can stand the test of time.

- Furthermore, the noise reduction capability of fiberglass ducts is another selling point. The material's sound-absorbing properties minimize the transmission of air noise, enhancing indoor comfort and acoustics. This is particularly beneficial in commercial settings where noise control is critical.

- The Extreme Power Jackhammer A Revolution in Demolition Technology

- Furthermore, the versatility of FRP allows for customization in design and capacity

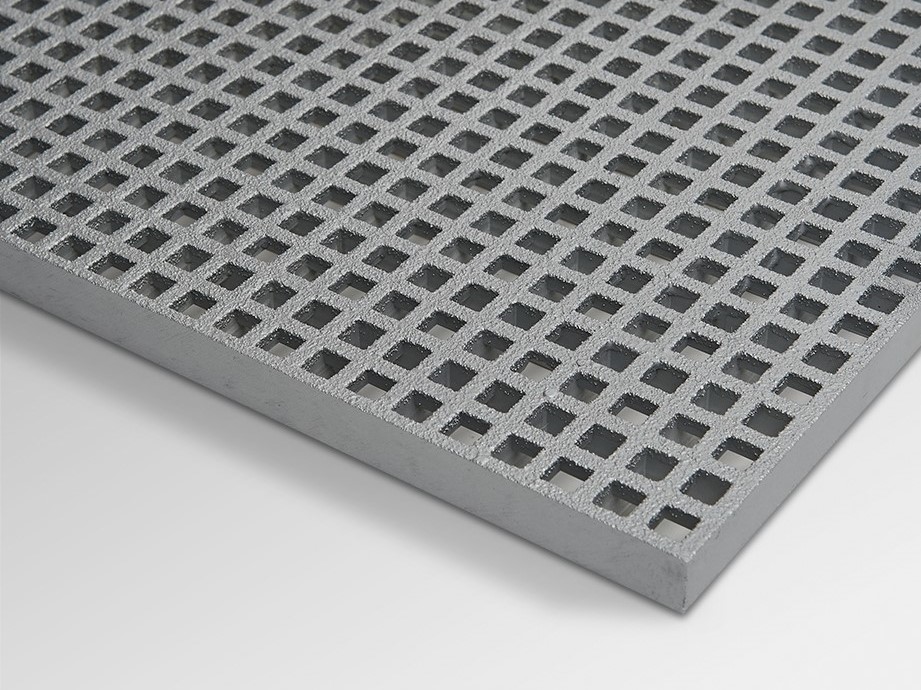

FRP Molded Grating adalah material yang menggabungkan serat fiber dengan resin, pigmen, serta zat aditif lainnya kedalam molding, sehingga menghasilkan produk grating dengan ukuran penal molding yang digunakan, FRP Molded Grating ini memiliki massa yang ringan, tahan korosi, dan tahan terhadap kondisi lingkungan yang keras. Dengan grating yang terbentuk presisi, FRP Molded Grating menawarkan kekuatan struktural yang tinggi dan sifat anti-slip, menjadikannya pilihan ideal untuk berbagai aplikasi industry dan komersil.

hard rock drill bit. In construction, they facilitate the creation of foundations for towering skyscrapers and complex underground infrastructure. In mining, they aid in extracting valuable minerals from the earth's depths, contributing significantly to global economic growth.

hard rock drill bit. In construction, they facilitate the creation of foundations for towering skyscrapers and complex underground infrastructure. In mining, they aid in extracting valuable minerals from the earth's depths, contributing significantly to global economic growth. Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance

Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance fiberglass car. This durability means fewer trips to the repair shop and a longer lifespan for the vehicle, providing economic benefits for owners in the long run.

fiberglass car. This durability means fewer trips to the repair shop and a longer lifespan for the vehicle, providing economic benefits for owners in the long run.The hard carbon aerogel can maintain the super-elasticity in harsh conditions, such as in liquid nitrogen. Based on the fascinating mechanical properties, this hard carbon aerogel has promise in the application of stress sensors with high stability and wide detective range (50 KPa), as well as stretchable or bendable conductors. This approach holds promise to be extended to make other non-carbon based composite nanofibers and provides a promising way of transforming rigid materials into elastic or flexible materials by designing the nanofibrous microstructures.

This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported

This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported grp fan.

grp fan.